- Description

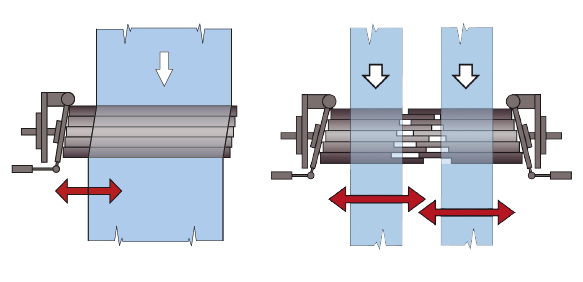

- Function drawing

Function

Guide profiles arranged around the circumference form the basis of the web guiding. In the basic version, the guide profiles are fixed to a guide plate so that they can be adjusted to the side via an actuating drive.

If two actuating drives are used, two webs can be controlled independently of each other, or a transversely elastic web can be guided based on a target width.

Area of use

Thanks to the minimum stress applied to the material by the segmented roller guider, the ELSMART system for web guiding and spreading can be used in practically all production processes.

Application

Segmented roller guiders can be used freely in terms of position. Wrapping of 90° is always required. Entry point 90°, exit point 180°. The infeed path should be the equivalent of at least one web width. By contrast, the exit should be kept as short as possible. Curled edges can be uncurled in the infeed plane with the aid of an additional spreading device.

Web guiding only

The version with undivided guide profiles across the full web width offers a particularly costeffective solution for web guiding only.

Two-web operation

With this design two webs can be controlled independently of each other using split guiding slats and two independent drives. Spreading is not possible in this mode.

Legend

K = Web correction | α = Correction angle | AB = Operating width | BB = Belt width | NB = Nominal width | L1 = Infeed path | L2 = Exit path

1 = Pivot point | 2 = Infeed conveyor belt | 3 = Segmented roller guider | 4 = Sensor | 5 = Fixing conveyor belt | 6 = Actuating drive

Web guiding only Two-web operation