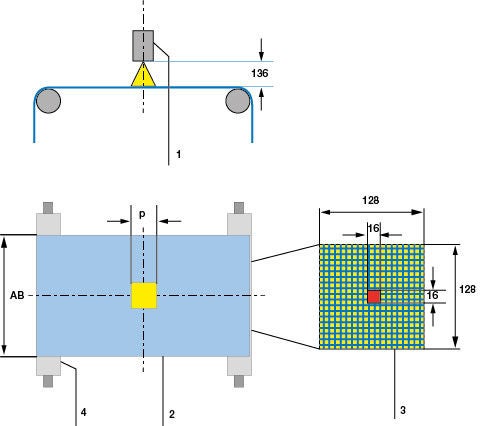

- Description

- Function drawing

Function

A matrix camera with integrated LED illumination for incident lighting detects the stitch and thread density on a moving web without touching the product. A controller compares the actual value with the target value set and outputs a corresponding speed target value to the overfeed roller. Because the camera cannot be mounted after the overfeed roller for space reasons, control of the thread/stitch density is only open-loop and not regulated. After the process, there is also a further camera for checking the stitch/thread density and automatically adjusting the target value on the infeed.

Area of use

Pick and course counter systems are typically used in the textile industry in the area of finishing in the following machines:

- Stenters

- Compactors

- Sanforizing machines

Application

A constant web tension at the scanning position is absolutely essential for precise acquisition of the stitch and thread density. The tension can be kept constant using a dancer position or a web tension control. To acquire the thread density, the camera is to be mounted on the infeed under the bridge before the feed roller, centered in relation to the web width. For the check on the outfeed, the camera is to be positioned before the last transport drive in front of the plaiter or rewinder. At this position, the web tension should be as low as possible and constant.

Legend

1= matrix camera | 2 = field of view | 3 = field of view zoom | 4 = guide roller | AB = operating width | p = thread and stitch density