- Description

- Function drawing

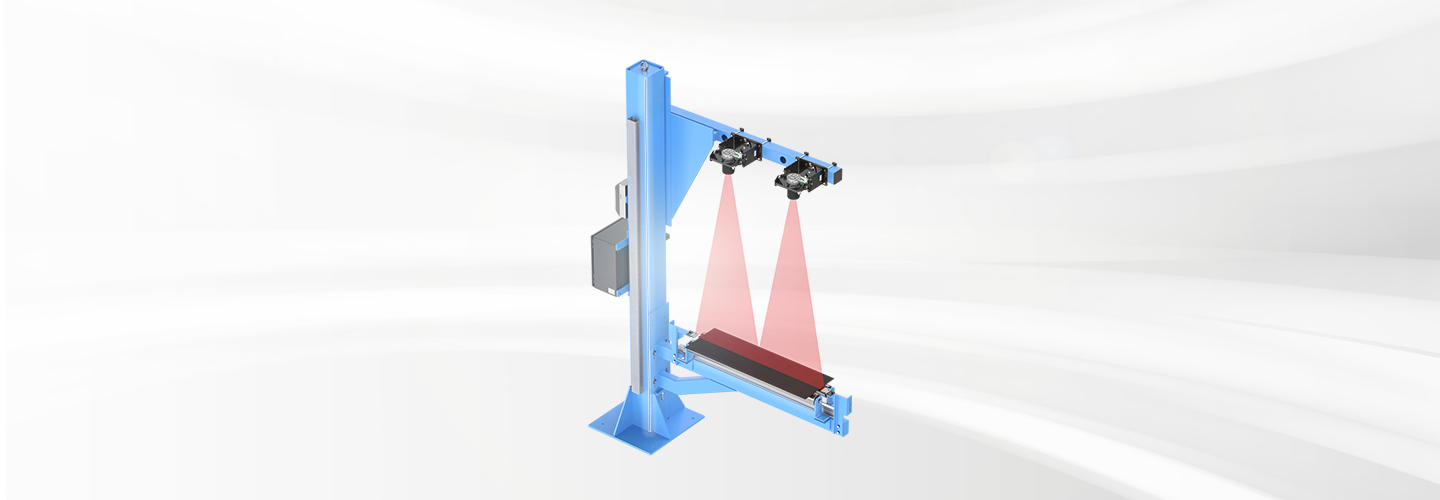

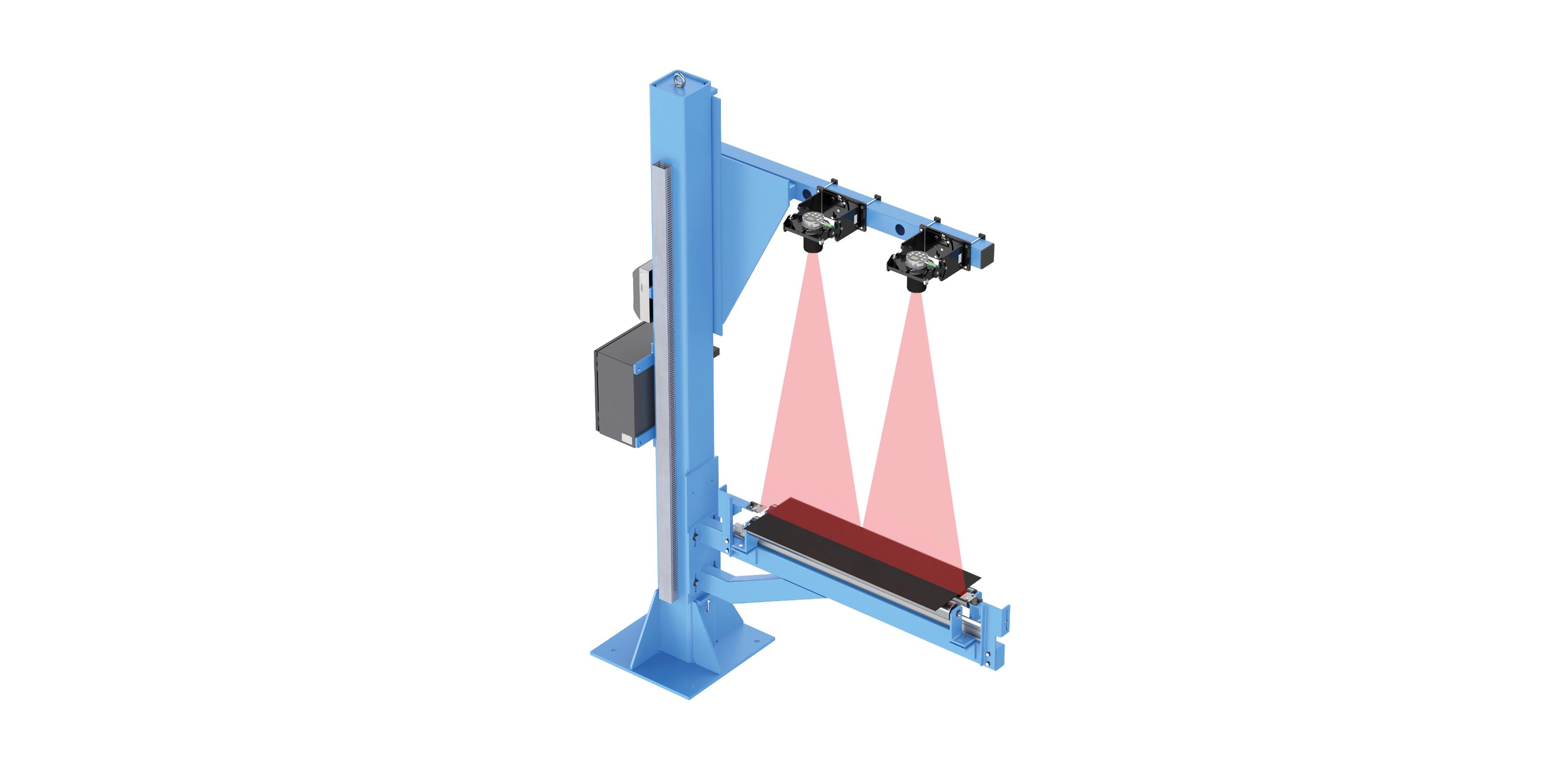

Function

Highly compact CCD cameras or wide band sensors contactlessly measure the material edges and supply one or more width values, depending on the requirements. These values can be displayed or also provided on an output for the purpose of quality control. Width monitoring is also possible with our systems.

Area of use

Web width measurement systems are used wherever the width of non-transparent webs must be monitored precisely and continuously.

Application

An interruption in the conveyor belt is necessary for width measurement systems. The web is measured using transmitted light and its height must not fluctuate at the measuring point.

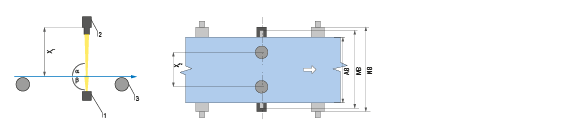

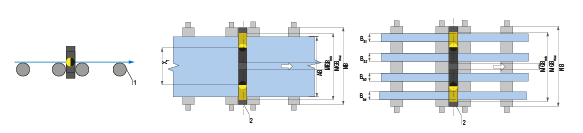

Width measurement with CCD cameras

Legend

AB = Operating width (conveyor width) | MB = Measuring range | NB = Nominal width | X1 = Distance, web surface – cameras | X2 = Distance, cameras | α = Angle, web surface – camera | β = Angle, web surface – light transmitter | 1 = Light transmitter | 2 = CCD line scan camera | 3 = Guide roller

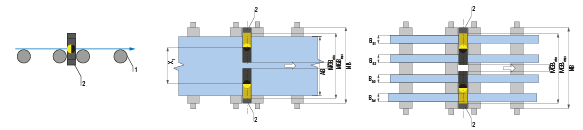

Width measurement with wide band sensor FE 46

Legend

AB = Operating width (conveyor width) | MBGmin = Total measuring range, min. | MBGmax = Total measuring range, max. | NB = Nominal width | X1 = Distance, sensors (center of measuring range) | 1 = Guide roller | 2 = Wide band sensor FE 46 | BSn = Width, strips 1 - n

Width measurement with wide band sensor FR 60

Legend

AB = Operating width (conveyor width) | MBGmin = Total measuring range, min. | MBGmax = Total measuring range, max. | NB = Nominal width | X1 = Distance, sensors (center of measuring range) | 1 = Guide roller | 2 = Wide band sensor FR 60 | BSn = Width, strips 1 - n