- Description

- Function drawing

Function

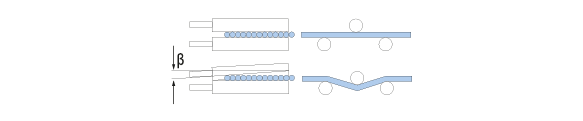

The edge spreading system EPILiner consists of two spreader units, each of which has a threefinger roller arrangement. The two fixed rollers are always in contact with the cord, the moving roller engages in the edge area of the cord. The width of the cord can be controlled by varying the bite angle of the roller. Spreading can be optimized by manually adjusting the correction angle.

Area of use

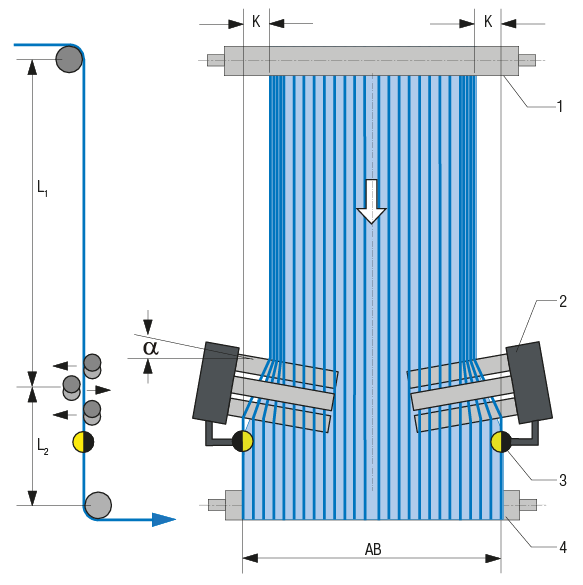

In particular on calender lines before the calender gap and in hot-stretching lines before coating or before the rewinder, the use of edge spreading systems is essential to ensure even cord distribution.

Application

The EPILiner edge spreading system can be mounted in all positions. The infeed path should be the equivalent of at least half a web width, while the exit path should be kept as short as possible. Optimal web width control can only be achieved with the aid of a web guider arranged before the spreading system.

Legend

K = Web correction | AB = Operating width | L1 = Infeed path | L2 = Exit path | 1 = Infeed roller | 2 = Edge spreading system EPILiner | 3 = Sensor | 4 = Locking roller | α = Correction angle | β = Bite angle