- Description

- Function graphic

- J-box for the accumulation of woven fabrics, non-woven fabrics, carpet and technical textiles before and after the production process

- Frame construction with closed C profile, also for use as a cable duct

- Dancer position control for tension control

- Integrated web guiding with web guider or segmented roller guider with spreading

- Stainless steel J-box with plastic slideways for wet and dry webs

Function

The task of J-boxes is to store woven fabrics, non-woven fabrics, carpet and technical textiles, in order to ensure a continuous production process when changing rolls.

Area of use

The area of use ranges across all textile equipment systems in the infeed and exit.

Application

J-boxes are are equipped with infeed tensioning units, to manage filling.

After the J-box, a web guiding system (optionally with spreading device) is required, to transfer the material web, spread and in the right position, to the downstream process.

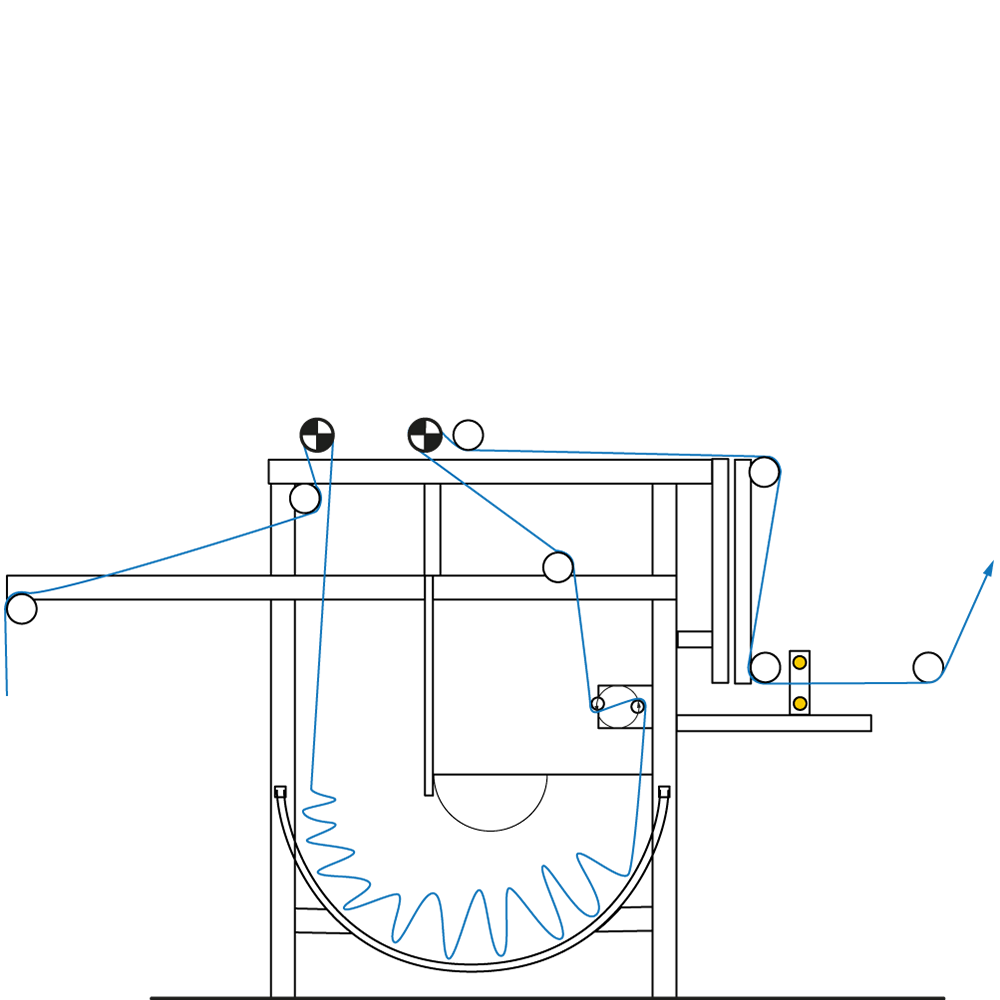

Infeed J-box for carpet

Infeed J-box for carpet

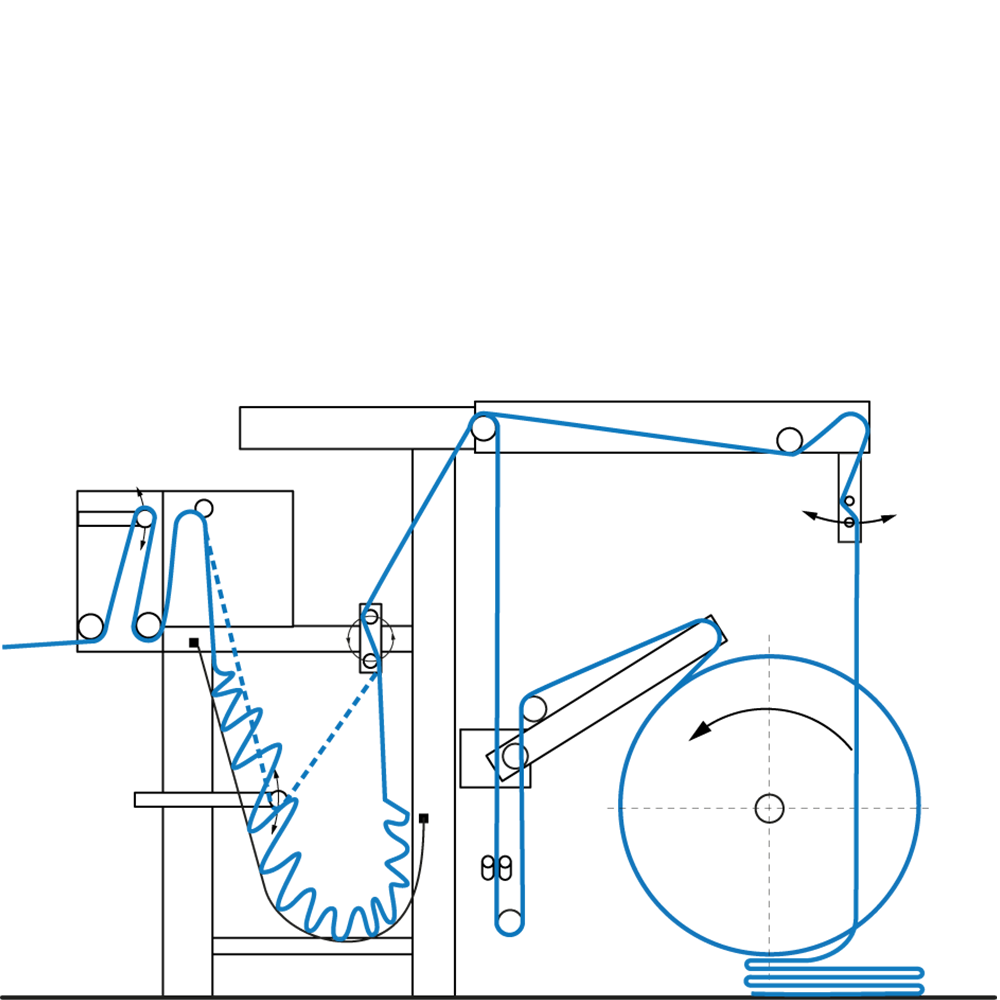

Exit J-box with traction unit, plaiter and surface winder

Exit J-box with traction unit, plaiter and surface winder

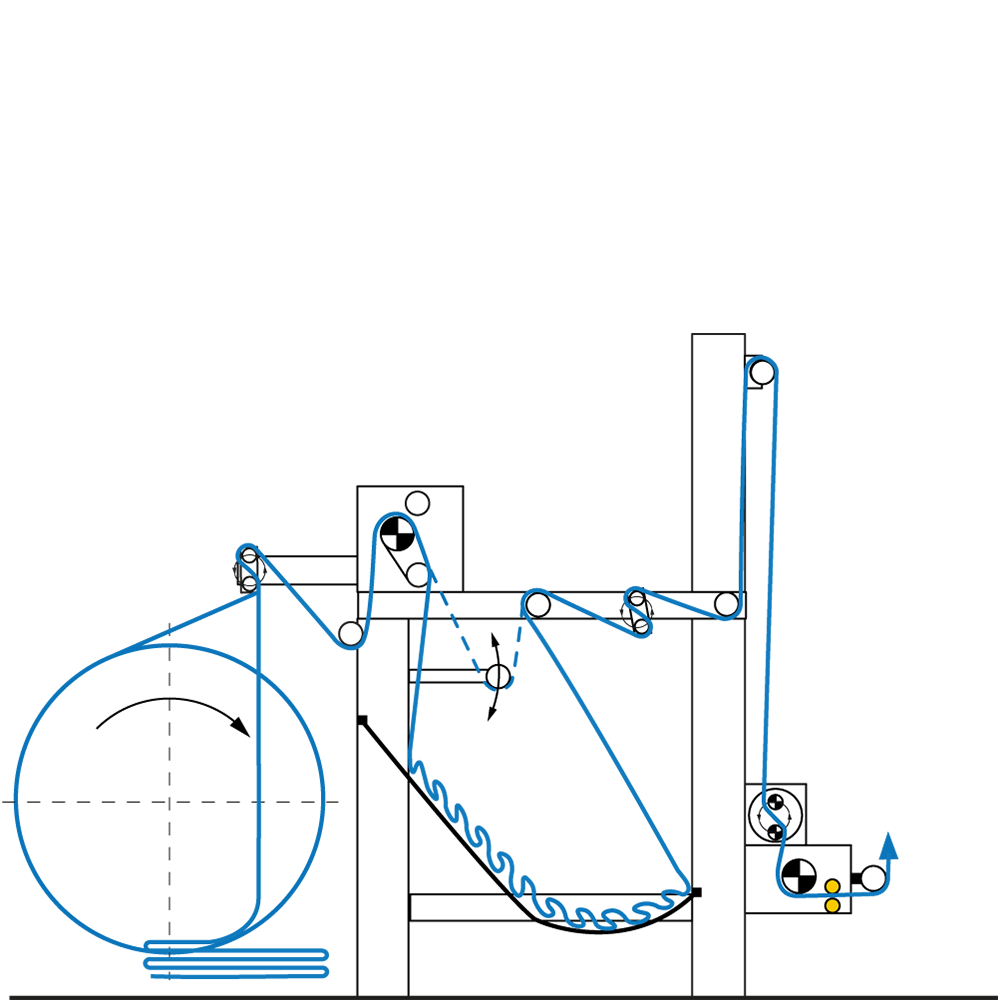

Infeed J-box for woven fabrics

Infeed J-box for woven fabrics