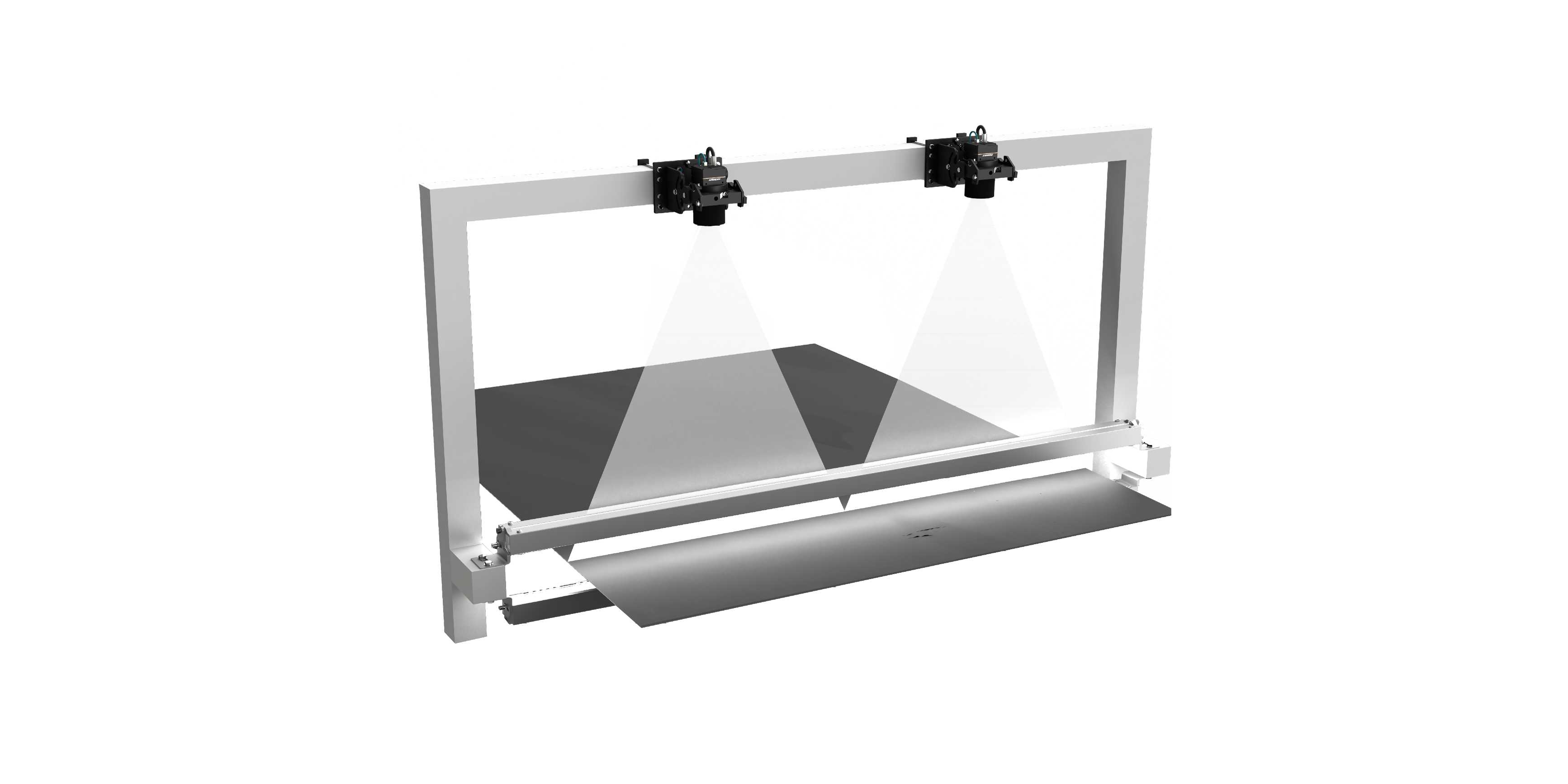

- Description

- Function drawing

Function

The surface inspection system RSI1 uses a series of color line scan cameras and very powerful LED light transmitters to inspect the rubber surfaces and to detect wetting defects (areas of the surface where the rubber is missing) or foreign objects such as pieces of color film. All defects detected are documented together with their position and a log can be prepared for every reel produced.

The defect detection system RSI2 uses a series of monochrome line scan cameras OL 91. The emphasis of this system is on the detection of defects on calender lines.

Area of use

Surface inspection systems are used preferably on calender lines or cutting systems.

Application

The surface inspection systems RSI1/2 should be used in the area of the rewinder or unwinder. Depending on the requirements, the monochrome version RSI2 or the RGB version RSI1 can be used. The height of the material must be stable without fluctuations and it is necessary to interrupt the conveyor belt. A speed signal is required for the precise recording and measurement of defects.