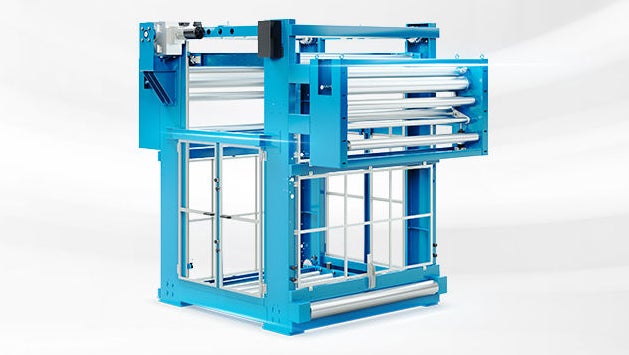

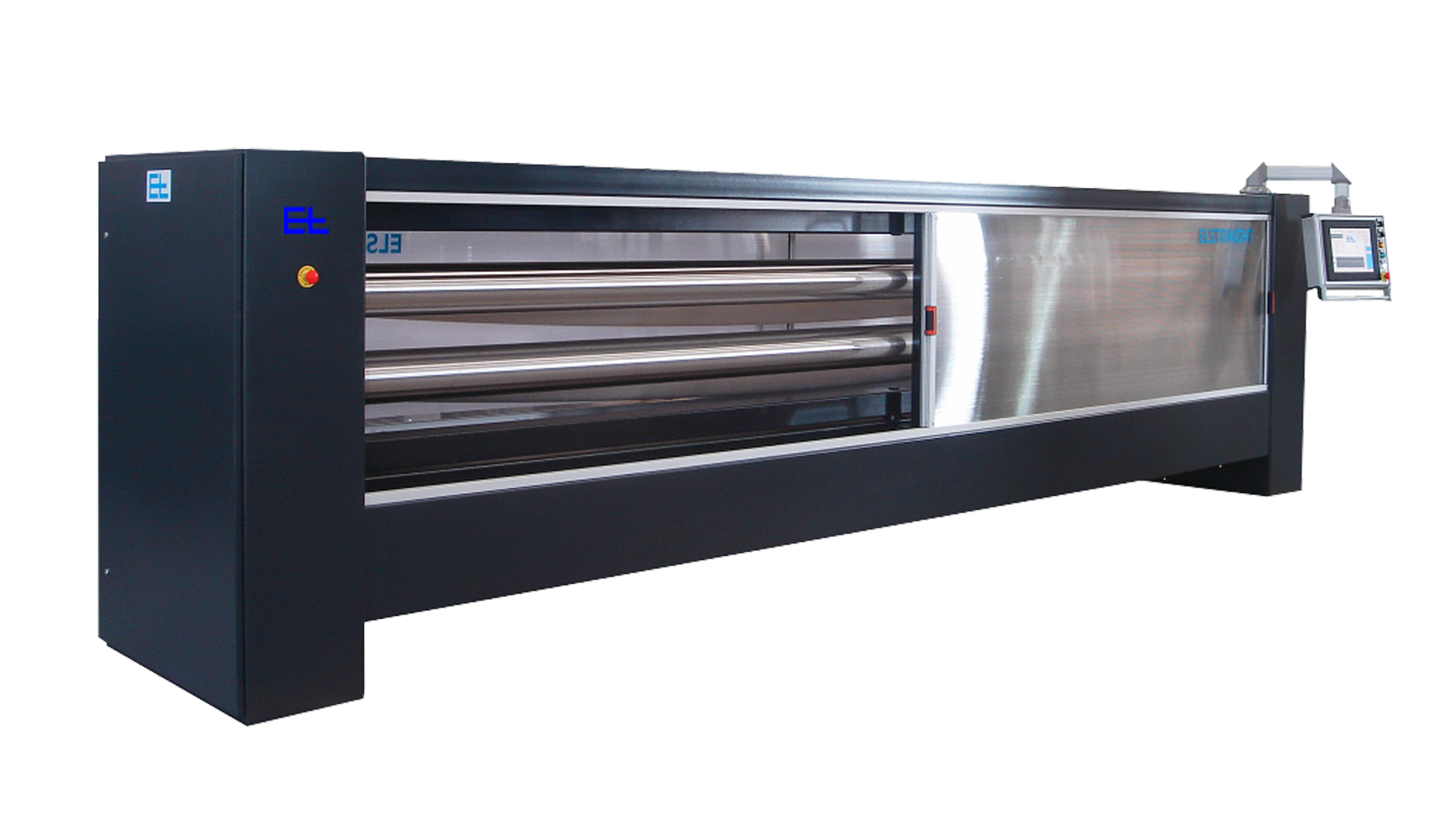

Exact web guiding and web tension-controlled drives are of the highest importance while printing carpets. They optimize the production process and reduce waste. At the end of the production process, as a rule edge trimming is necessary and, in some circumstances, also the logging of the web width. The use of a seam sensor can further optimize the yield of merchantable finished product by taking into account the positions of the seams.