- Description

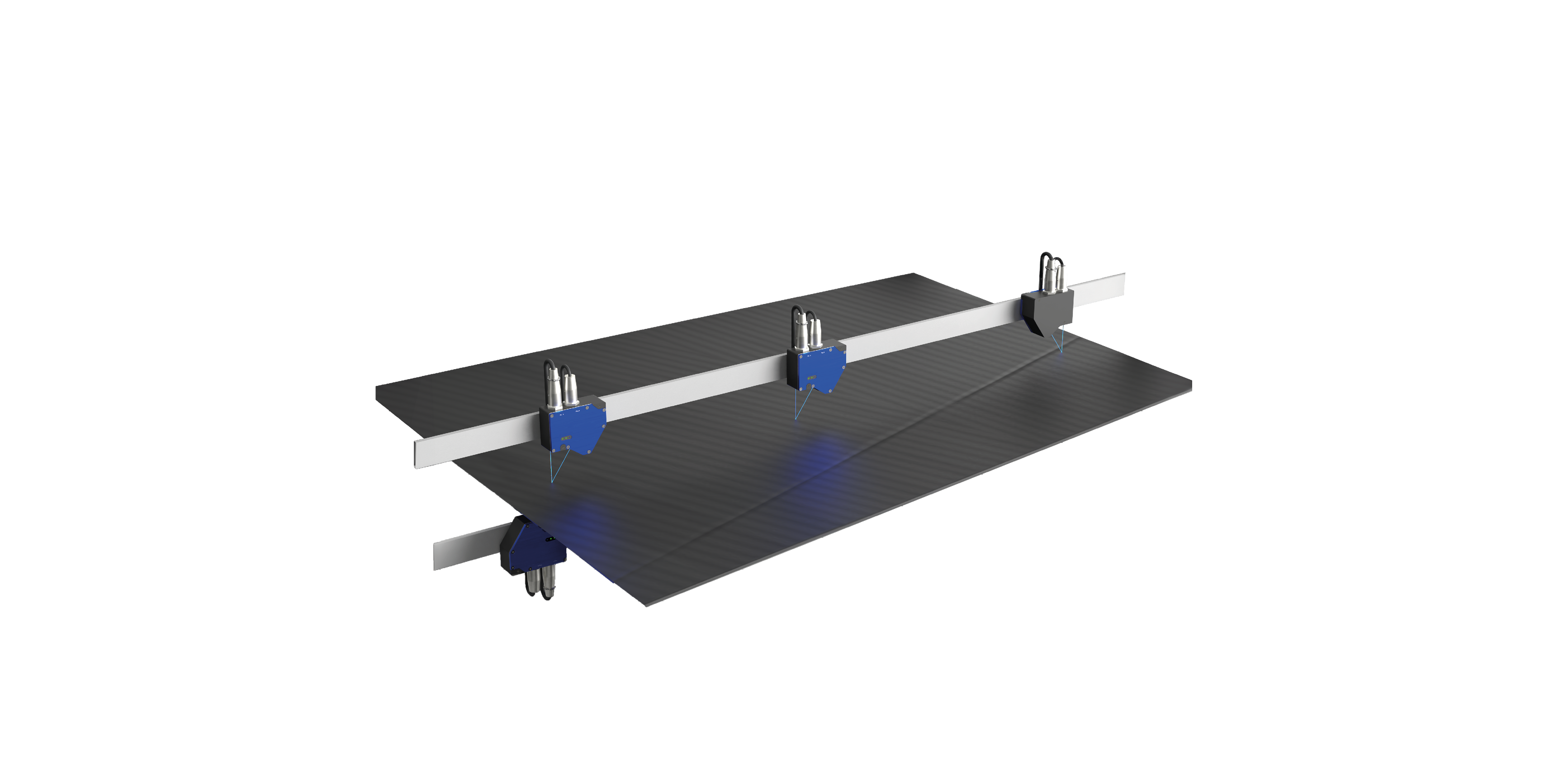

- Function drawing

Function

EL.SPLICE uses laser distance sensors to monitor the length of the overlap at the splice. This measurement system always consists of one or more sensor pairs with one sensor above the material and the other below. The overlaps are measured in the longitudinal direction by one, two or three sensor pairs in a gap between two conveyor belts.

Area of use

A typical application is in a cutting line immediately after the splice table. There the overlap is measured so the customer can optimize the production process.

Application

EL.SPLICE is normally mounted on the existing mechanical guide at the customer so that it is ideally adjusted to the actual material width. The height of the material must not fluctuate at the measuring point.

Legend

AB = Operating width | MB = Measuring range | NB = Nominal width |X1 = Distance, web surface – sensors | X2 = Distance, sensors | α = Angle, web surface – camera | 1 = Sensor | 2 = Guide roller