100% inspection systems are becoming ever more important due to the high requirements in the labeling market. The consequence of the challenging requirements is that, in many areas, goods may not reach the ultimate consignee without a 100% check. This hurdle presents many printers with a major challenge.

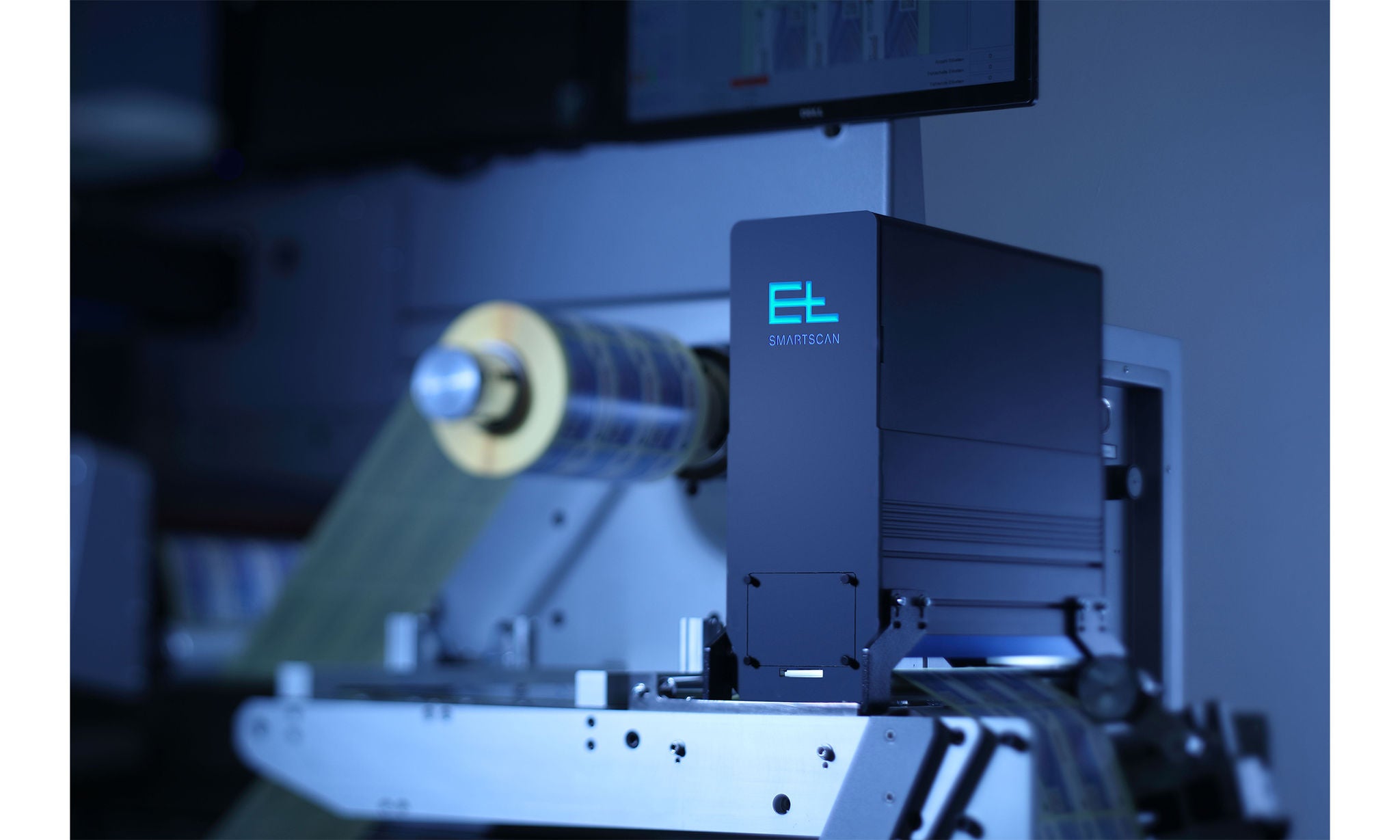

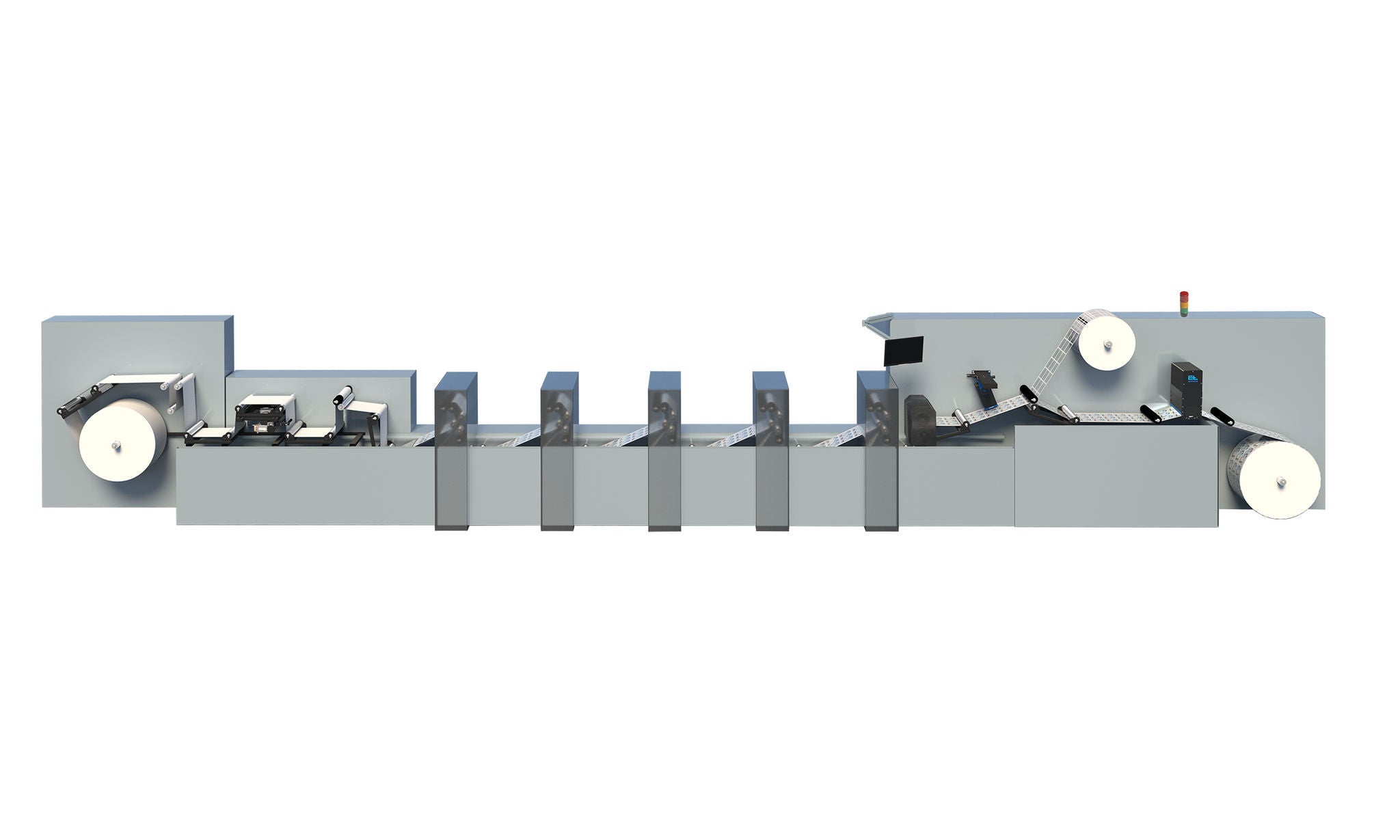

With SMARTSCAN, Erhardt+Leimer is offering an innovative solution that even goes beyond 100%. SMARTSCAN is the first 200% inspection system developed specially for narrow-web printing and finishing machines. The 200% inspection reliably detects print defects, damage to the material and missing labels. SMARTSCAN can be used not only for quality control in the labels market, but also for the checking of other printing applications, such as in packaging printing. The checking of unprinted, homogeneous materials, such as paper or film, is also possible.

SMARTSCAN – 200% print inspection

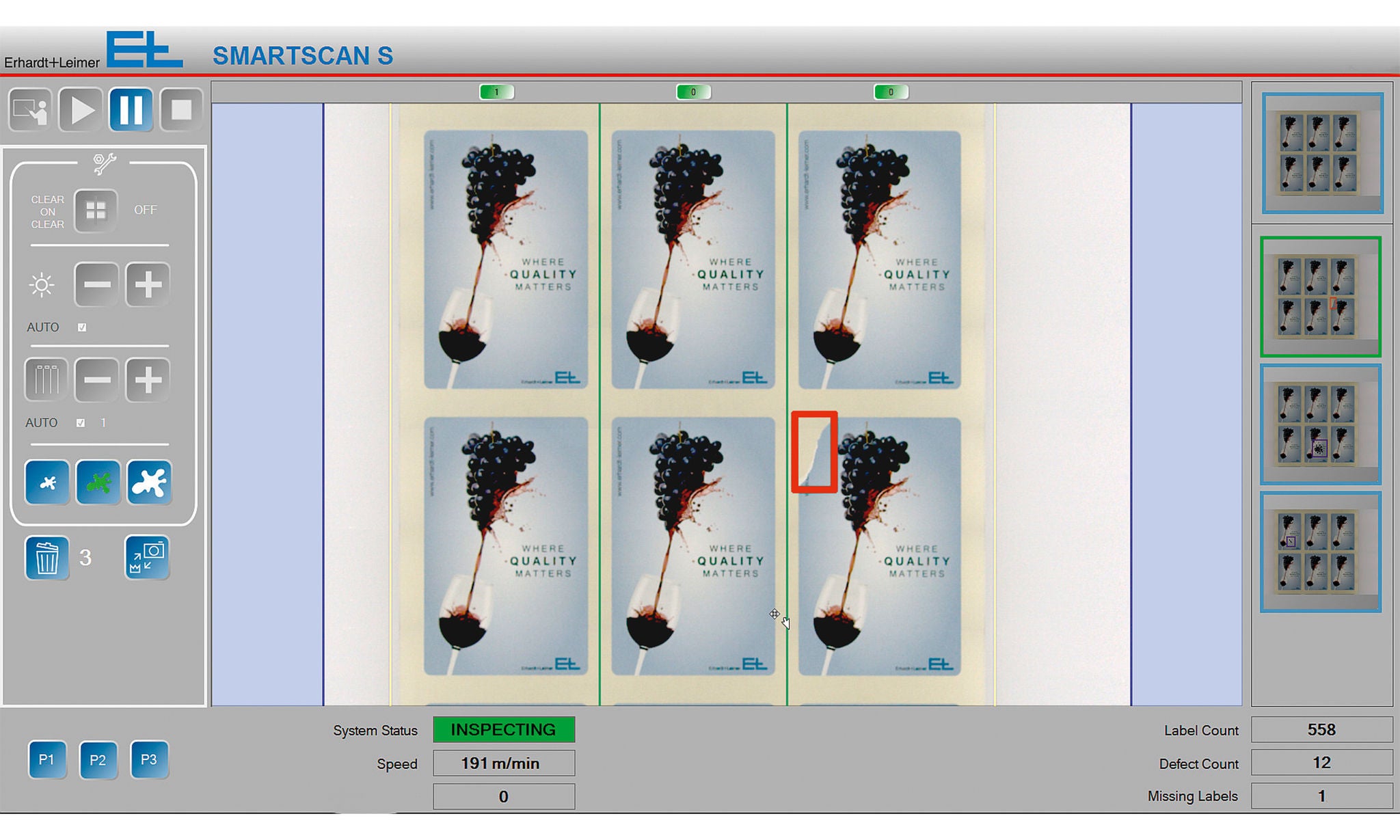

SMARTSCAN uses a unique, double image acquisition method for the inspection. Here, two image streams are acquired with a temporal offset – once with incident light and in parallel with transmitted light. Each of these image streams is compared with a dedicated reference image (golden template) and checked for defects.

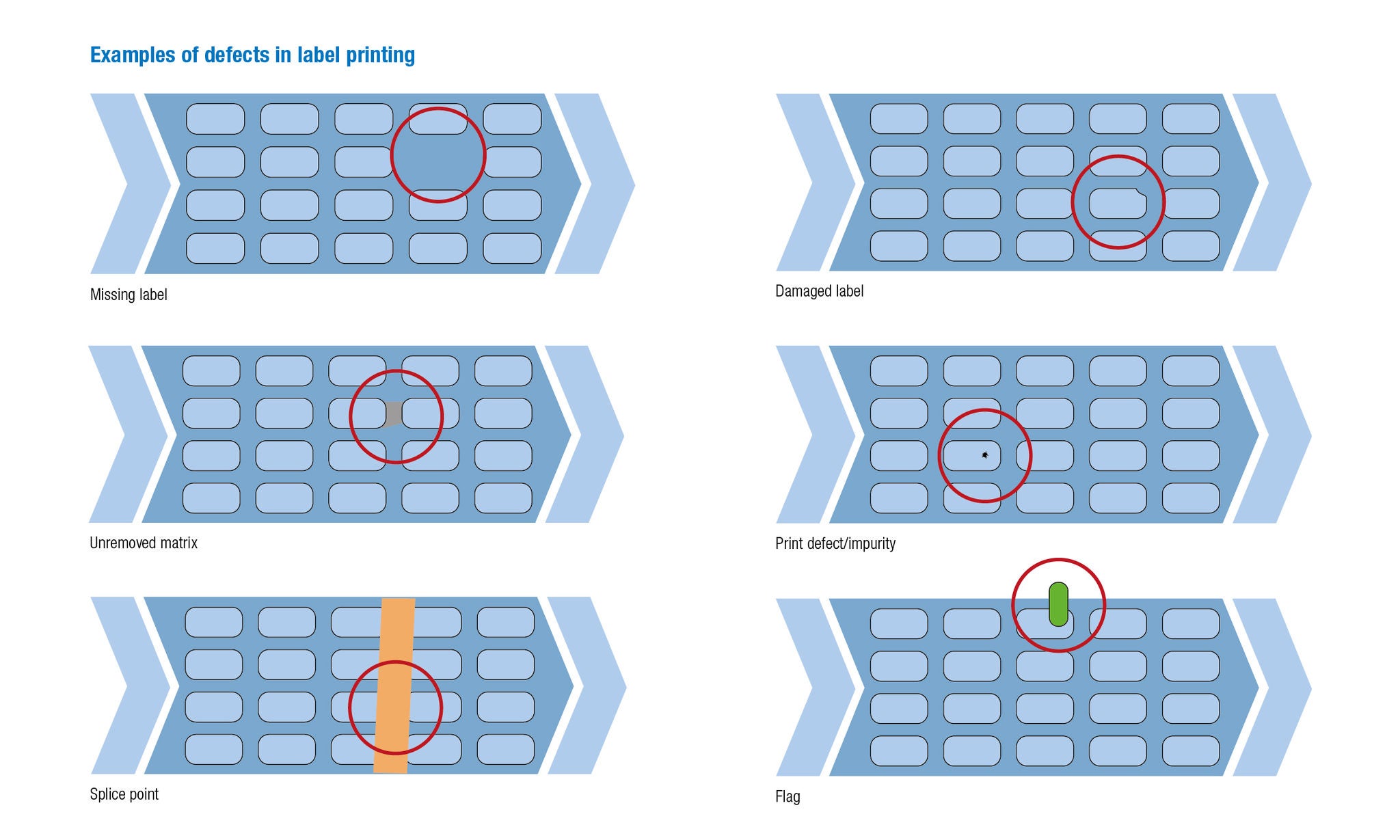

The advantage is that, along with classic print defects, also material defects such as damage in the label or on the carrier, unremoved matrix, offset on the die cutting position, splice points or residue/insects on the rear of the label become visible. There is also special hole detection for films and foil.

One-click operation

With just one click of a button, SMARTSCAN is set up and immediately ready for inspection. All necessary parameters are set automatically, so there is no need for any further manual intervention. Thanks to this automated operating concept, which is unique in the market, the user hardly has to invest any time and can concentrate on his actual work.

Write to us! We are looking forward to your message.

- Description

- Technical Data

- Camera system for 200% inspection on printing and finishing machines in label applications and narrow-web applications

- Safe defect detection through special LED illumination concept

- Suitable for paper labels and for transparent and clear-on-clear labels and glossy foils

- Defect classification, such as missing label, unremoved matrix, splice, flag, print defect, hole

- Simple system integration (no external technician required)

- Time-saving and fast operating concept (1-button setup)

- SMARTSCAN 4K – Increased solution for even more detailed defect detection

- SMARTSCAN UV – For the inspection of fluorescent colors, varnishes and other UV applications

Further functions

- Report Manager – PDF report to document the inspected rolls

- PDF comparison – Comparison of the camera reference image (Golden Template) with the PDF print template to detect defects in the printing plate, incorrectly chosen printing plates or to check foreign languages and character sets

- Surface inspection - For the inspection of unprinted materials

- Image storage function - Saving of freely selectable image areas

- Distance measurement function - Inline measurement of spacings, positions, repeat lengths of the web width

- Pinhole module - For improved detection of hole areas through the special 200% inspection technology

- Code module – To read barcodes and 2D codes

- And much more...

| Web width in mm | 180 mm & 265 mm / 350 mm / 470 mm / 510 mm & 560 mm / 660 mm / 680 mm & 790 mm |

| Field of view in mm | 190 mm (7") & 275 mm (10") / 360 mm (14") / 480 mm (18") / 520 mm (20") & 570 mm (22") / 670 mm (26") / 690 mm (27") & 770 mm (30") |

| Camera unit LxWxH | 330.8 x 154 x 418.3 mm / 430.8 x 154 x 418.3 mm / 530.8 x 154 x 418.3 mm / 630.8 x 154 x 418.3 mm / 730.8 x 154 x 418.3 mm / 830.8 x 154 x 418.3 m |

| Max. speed | Up to 600 m/min (depending on the system configuration) |

| Max. web offset | ±10 mm |

| Camera resolution | Up to 12 MP (depending on the system configuration) |

| Chip | RGB (color) |

| Wavelength range UV radiation | 365-370 nm LEDs (only with UV lighting) |

| Camera interface | Ethernet/USB-3 |

| Operating system | Windows 10 IoT Enterprise LTSC |

| Monitor | 22" LED touchscreen (HD resolution) |

| Monitor connection | DisplayPort |

| Operating voltage | 100-240 V AC, 50-60 Hz |

| Current consumption | 3.5 A |

| Temperature range | +0 °C to +45 °C |

| Transport/storage temperature | -30 °C to +70 °C (non-condensing) |

| Protection class | IP 20 |

| Voltage for inputs/outputs | 24 V DC |

| Max. current consumption of outputs | 50 mA |

| Defect types (examples) | Defective labels, printing defects, color defects, index defects, punching defects, insects, holes, barcode defects (1D + 2D), distance defect, UV and varnish defects, defects in RFIDs etc. |

| Material types | Paper, films (transparent, clear-on-clear, gloss films, opaque) |

"As the market leader in automation and quality assurance, we set the standards in printing, extrusion and converting.

With our new networking concept, we have now reached the next level of automation."

Dirk Schröder

Sales Operations Manager ELA

Sales Division Manager

Paper / Film / Special Markets

SMARTSCAN Features

Effortless setup: streamline print inspection with SMARTSCAN

Are you looking for an inspection system that does not tie up your team’s time resources?

SMARTSCAN offers an intuitive user interface and automatic system configuration for a quick and easy start-up, leaving the operators time to do their real work!

Key Benefits:

- Simple operation

- Automatic setup

- Ready to inspect in seconds

Targeted defect analysis: SMARTSCAN only finds the defects you are really looking for

Focus on what truly matters! SMARTSCAN's defect classification intelligently filters and displays only the defects relevant to your production process. Save time and boost your productivity with this smart filtering feature.

Key Benefits:

- Automatic defect classification

- Flexible classification settings

- Live view with detailed analysis

- Reduced scrap rates

Built-in code verification and enhanced quality control

In today's data-driven world, ensuring the integrity of 1D or 2D codes on labels is crucial for seamless product identification, tracking, and traceability. SMARTSCAN's automated code verification solution enables companies to guarantee the accuracy of the print, especially with serial codes, and eliminates the risk of costly claims.

Key Benefits:

- Automated code reading and verification

- Comprehensive defect detection and duplicate identification

- Control of static and dynamic codes

- Automatic creation of documentation for comparison with reference lists

Achieve precision with SMARTSCAN's measurement solutions

Precise measurements are essential for ensuring proper product alignment, compatibility with automation equipment in further processing steps, and adherence to industry standards. SMARTSCAN's array of measurement solutions provides businesses with the accuracy and reliability they need, and even offers a special placement control for RFID label producers.

Key Benefits:

- Cut to label edge measurement

- Web width measurement

- RFID position measurement

- Pinhole size measurement

SMARTSCAN's 200% inspection technology: uncovering hidden defects

Traditional print inspection methods often fail to detect subtle material or print defects that can compromise product functionality and brand reputation. SMARTSCAN's revolutionary 200% inspection technology takes defect detection to a completely new level, ensuring that even the most elusive imperfections are identified and eliminated.

Key Benefits:

- Reliable defect detection with dual image stream

- Defect classification for a better overview

- Pinhole defect detection at the highest level

- Special RFID position monitoring

- Reduced false positives and improved inspection accuracy

A major plus for IT and system security: Even if there is a power failure, virus attacks, targeted manipulation or operational defects, the SMARTSCAN security concept means that there is no risk of losing data or that SMARTSCAN is no longer ready for operation. The operating system, the SMARTSCAN software and the system data are located on the writeprotected C partition of the SMARTSCAN PC and are thus safe. It is only possible to write to the D partition, which contains the system parameters, order data and roll reports. If necessary, the original state can be restored in seconds by restarting SMARTSCAN. The operating system does not need to be shut down for this. The security concept makes SMARTSCAN very robust and reliable.