- Description

- Function drawing

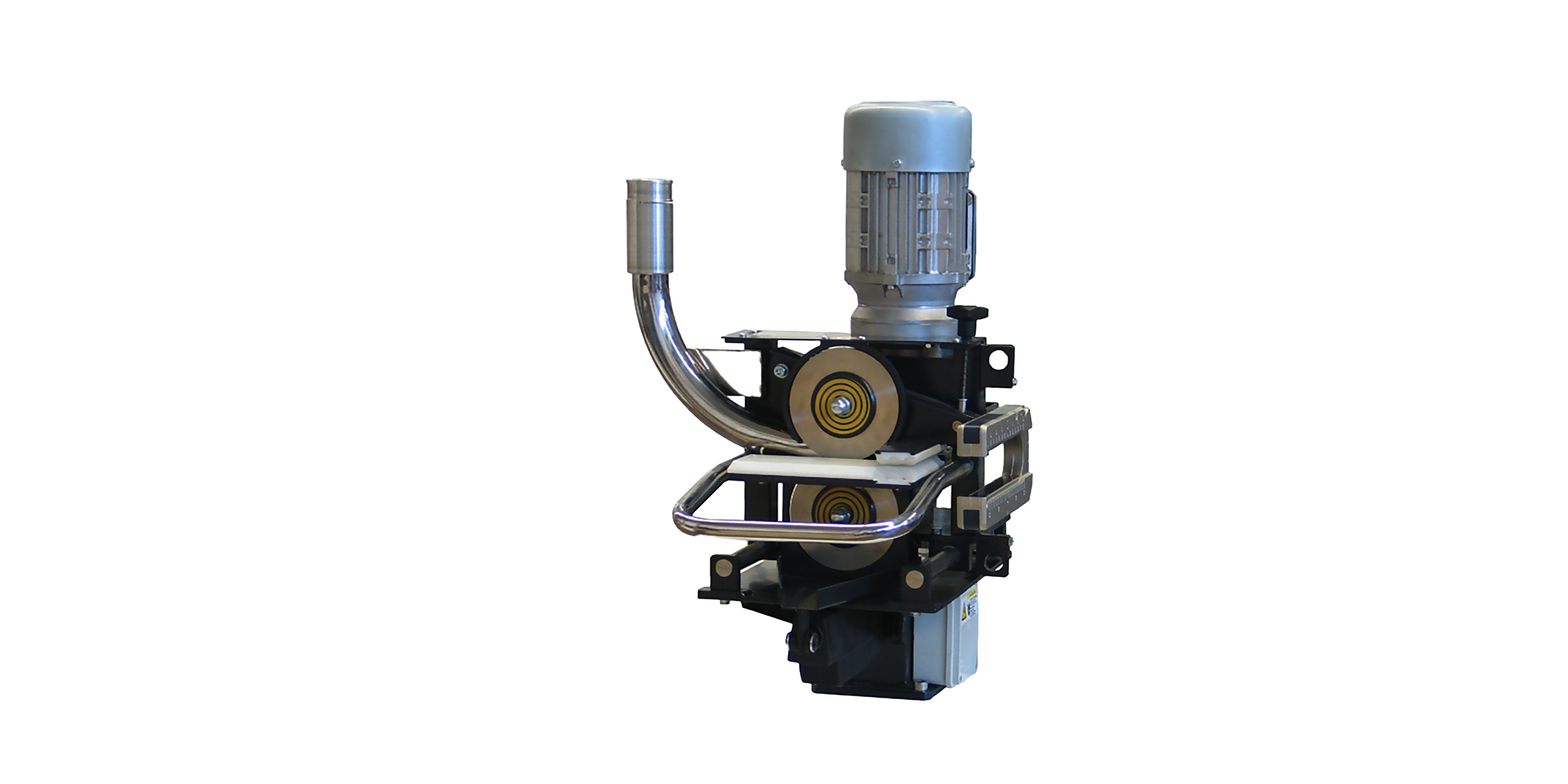

Function

The top blade is powered via a geared motor and drives the spring-mounted bottom blade. The device is always positioned in a user-friendly manner using a motor at the touch of a button or using automatic follow-up based on the web edge.

Minimal edge waste is only achieved when the web edge is fully unrolled. E+L can offer an integrated mechanical spreading unit (E+L patent) for this and, alternatively, a pneumatic solution for its cutting systems.

Noise-dampened side channel compressors are available for the removal of any edge waste.

Area of use

The edge cutting technology is used at the outfeed of the following systems: Stenter, compactor and sanforizing systems.

Application

At the end of the machine, the web is removed from the pins with an initial path roller. Two further path rollers form the cutting level. See graphic alongside.

Legend

1 = Guide roller | 2 = Three-phase drive | 3 = Shear cut | 4 = Edge sensor | 5 = Actuating drive for follow-up | AB1 = Operating width | AB2 = Operating width after edge cut | NB = Nominal width | F = Web tension | VB = Web speed | VS = Cutting speed