Today, the manufacturers and users of machines for processing web-type materials are confronted with ever increasing demands: production processes should be even faster, while at the same time performed with greater precision, the quality of the finished product further improved while personnel, waste and, above all, downtimes, should be reduced to a minimum. A decisive contribution to the fulfillment of these prerequisites is made by web tension control systems by Erhardt+Leimer.

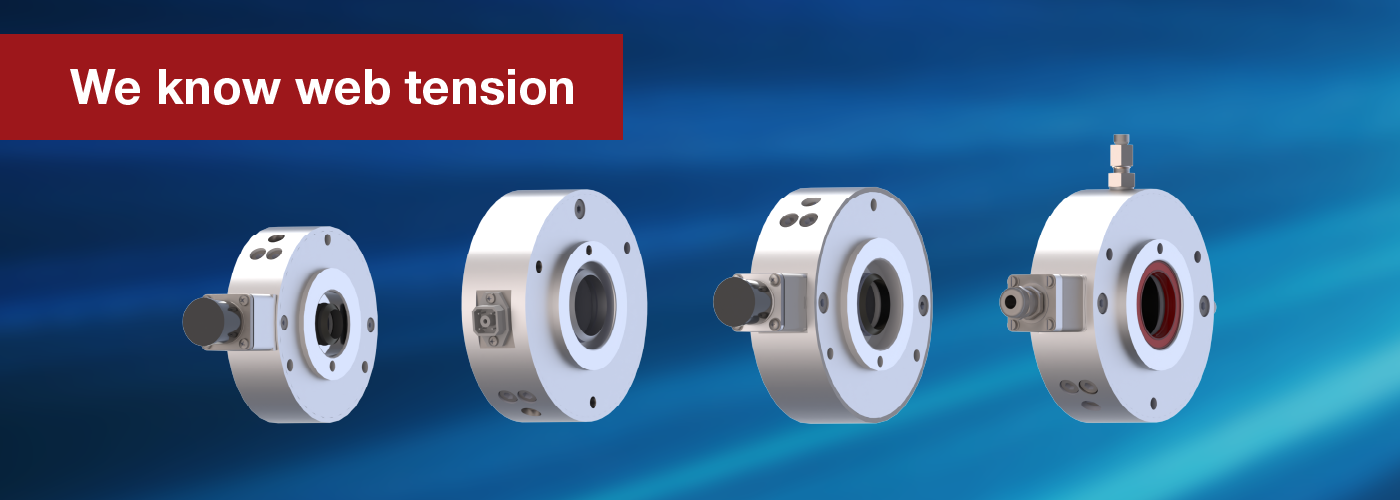

The ELTENS load cells

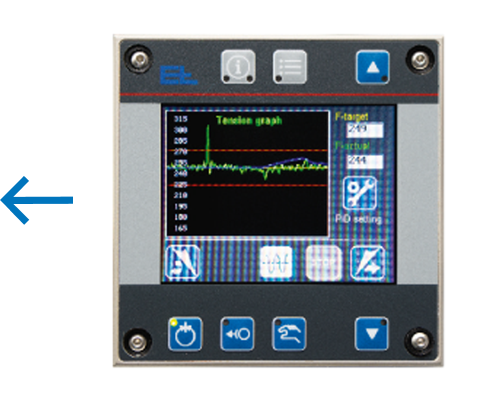

ELTENS is Erhardt+Leimer’s comprehensive web tension monitoring and control system. We offer a wide range of load cells for different applications and production requirements. Combined with many options for amplifying and controlling units, you get a full service package that solves all your web tension problems and improves production quality and quantity.

PD 21/22

- 0.05 - 10 kN

- broad web

- steel

- one & both sides

- for all applications

PD 23/24

- 0.1 - 3 kN

- broad web

- stainless steel

- one & both sides

- wet environment

PD 25/26

- 0.1 - 1.5 kN

- broad web

- aluminium

- one & both sides

- for battery industry

PD 27

- 60 kN

- narrow web

- steel

- one side

- single side mount

PD 50

- 0.08 - 2.0kN

- broad web

- aluminium

- one & both sides

- easy roller mounting

PD 21/22

| PD 23/24

| PD 25/26

| PD 27

| PD 50

| |

| Nominal measuring force | 0.05 - 10 kN | 0.1 - 3 kN | 0.1 - 1.5 kN | 60 kN | 0.08 - 2.0 kN |

| Web width | wide web | wide web | wide web | narrow web | wide web |

| Material | steel | stainless steel | aluminium | steel | aluminium |

| Bore type | one & both sides | one & both sides | one & both sides | one side | one & both sides |

| Application | for all applications | wet environment | battery industry | single-side mount | easy roller mounting |

| More Information | More Information | More Information | More Information | More Information |

Find even more Erhardt+Leimer web tension products here:

Quick expert info & contact

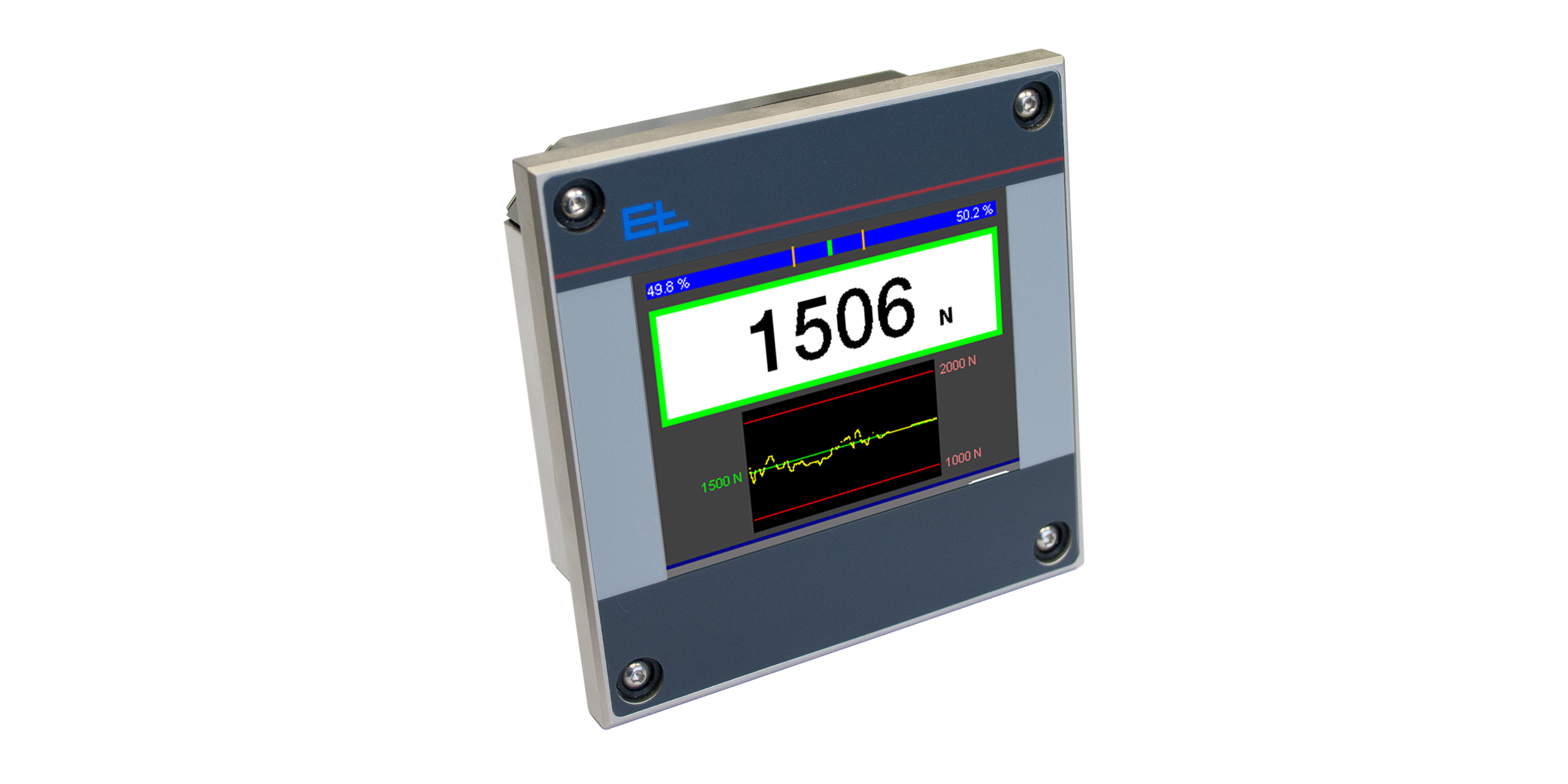

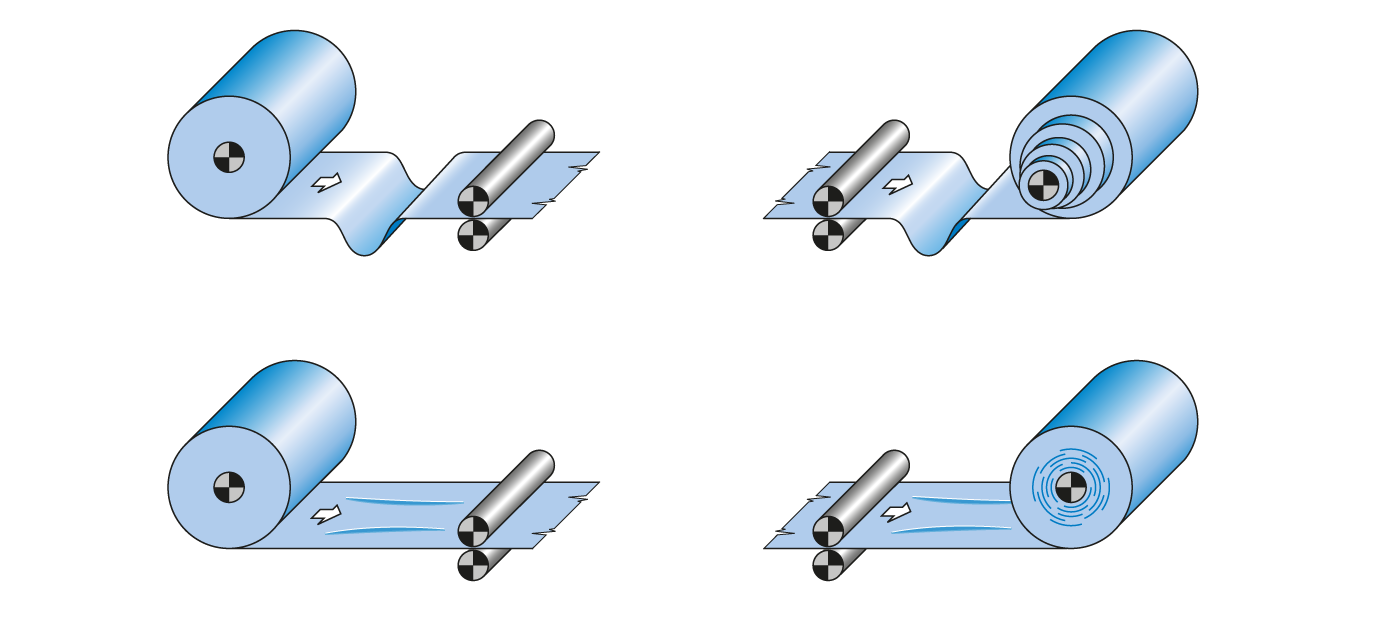

Controlled web tension is essential

Typically, web-type materials are fed from a roll to the machine, finished and then rewound. At each stage, web tension errors may occur that may lead to malfunctions and quality impairments. The elimination of these sources of error and ensuring a constant web tension during the production process is the task of E+L web tension control systems. Depending on the material type, application and task, Erhardt+Leimer offers a variety of systems with the latest technology: For decisively more quality and productivity that pays off.

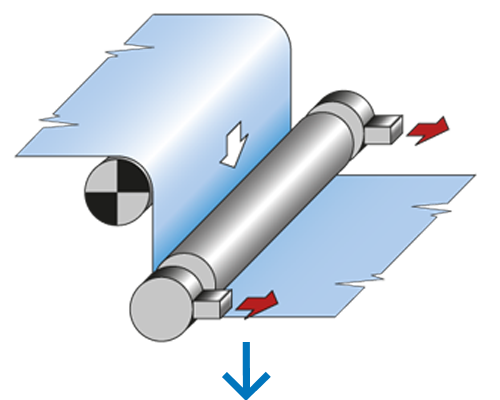

Web tension after the unwinder

- Insufficient web tension causes slack in front of the transport drive

- If the web tension is too high, longitudinal creasing and textile web deformation may be caused

Web tension on the rewinder

- If web tension on rewinding is insufficient, roll telescoping may occur

- Excessively high tensile forces damage the inner windings

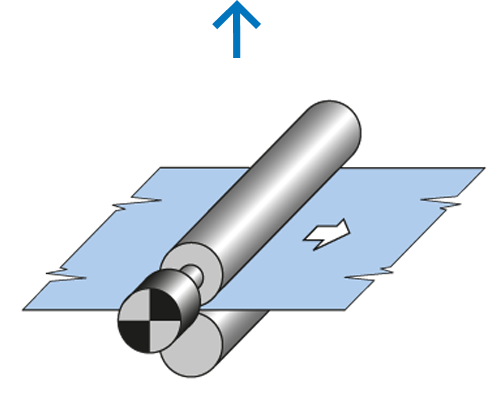

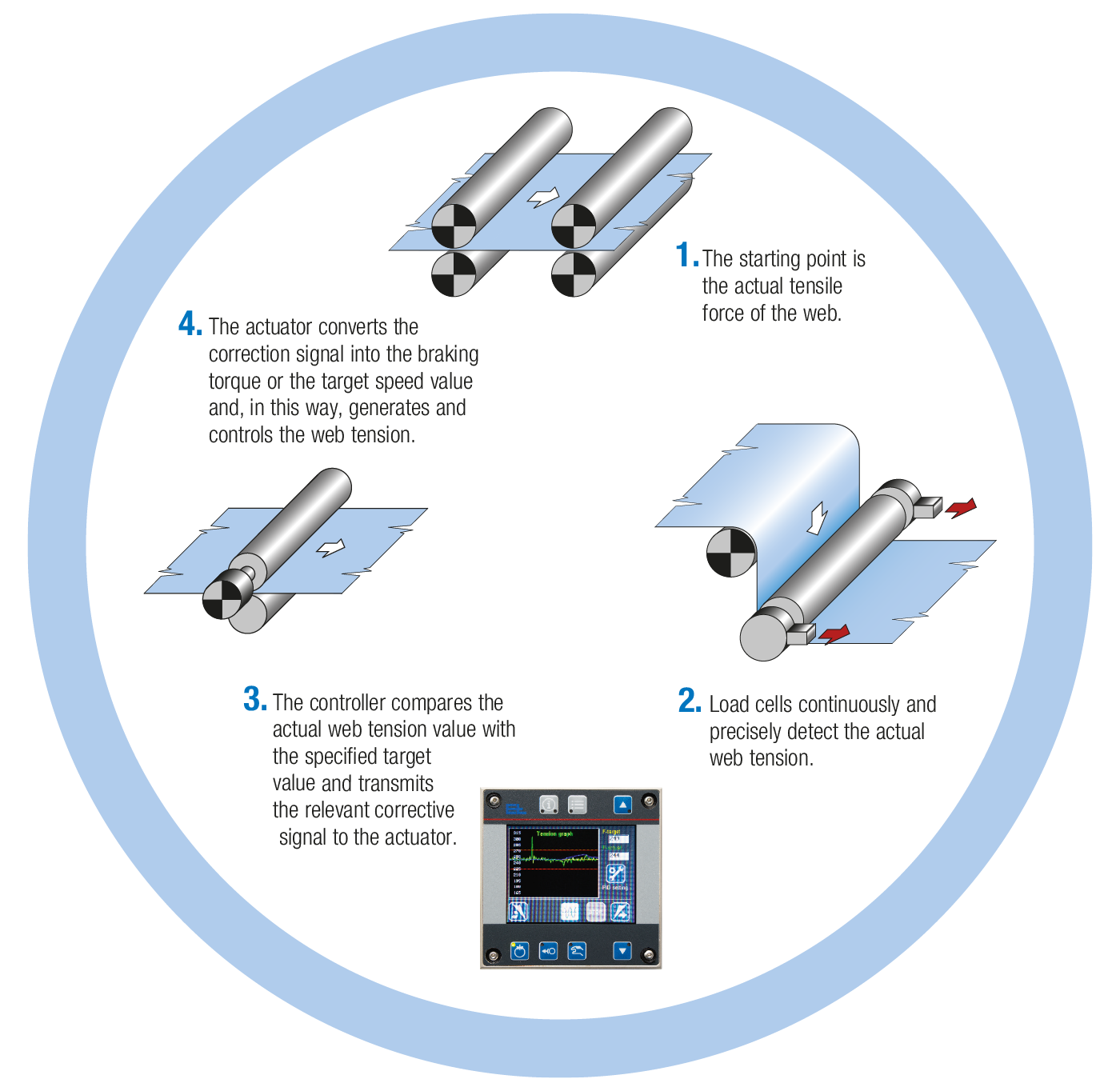

The solution: a continuous control loop

Any automation of a controller is based on the principle of a simple control loop. Even the most complex of tasks may be reduced to this control loop.

"As the market leader in automation and quality management, we know that precise web tension in the production process is the key to your product quality. Accuracy, reliable measuring equipment and state-of-the-art technology are the guarantees of success that all Erhardt+Leimer customers can count on."

Dirk Schröder

Sales Operations Manager ELA

Sales Division Manager

Paper / Film / Special Markets

The perfect ELTENS package for your application

Bundle 1

- Anwendung

- Details

- etc.

Bundle 2

- Anwendung

- Details

- etc.

Bundle 3

- Anwendung

- Details

- etc.

Bundle 4

- Anwendung

- Details

- etc.

The ELTENS calculator

Depending on the respective requirements and conditions of your starting material, ELTENS offers a wide range of systems and solutions for web tension measurement and control. The resulting web forces can be calculated quickly and easily using our free calculator.